Technical & Management Solutions

Less Carbon

Extend Asset Life

|

Cedro delivers engineering, maintenance and project consulting for Oil & Gas, Mining and Marine, helping you operate safer, longer and at lower cost.

Who we are

A group of highly qualified engineers and professionals with experience in

projects (EPC), modification and maintenance of equipment (Brownfield

projects).

The professional qualifications of Cedro’s team ensure compliance with

the requirements and standards across a wide range of sectors: Oil & Gas,

Shipbuilding and Mining, as well as project management consultancy.

Technical and operational knowledge are essential factors for the

preparation of a realistic schedule for meeting our clients’ deadlines.

Expertise also allows the team to minimize risks, foresee project

constraints, meetthe goals and budget accordingly.

We believe that the wisdom gained through experience, combined with

empowering future generations, are essential factors to building a

stronger and more prosperous society.

About Cedro

We provide technical and management solutions that help our partners meet contractual, operational and budgetary goals. Our team combines field experience, continuous improvement and process optimization to reduce CAPEX, OPEX and carbon emissions.

What we do

Services

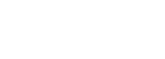

We support our clients throughout the full lifecycle of their equipment – from preservation and storage to maintenance and end-of-life decisions. Our focus is to keep critical assets safe, reliable and compliant while reducing downtime and operational risk.

- PSM (Preservation / Storage / Maintenance)

- Corrective repair

- Operational troubleshooting

- Commissioning & decommissioning

Engineering

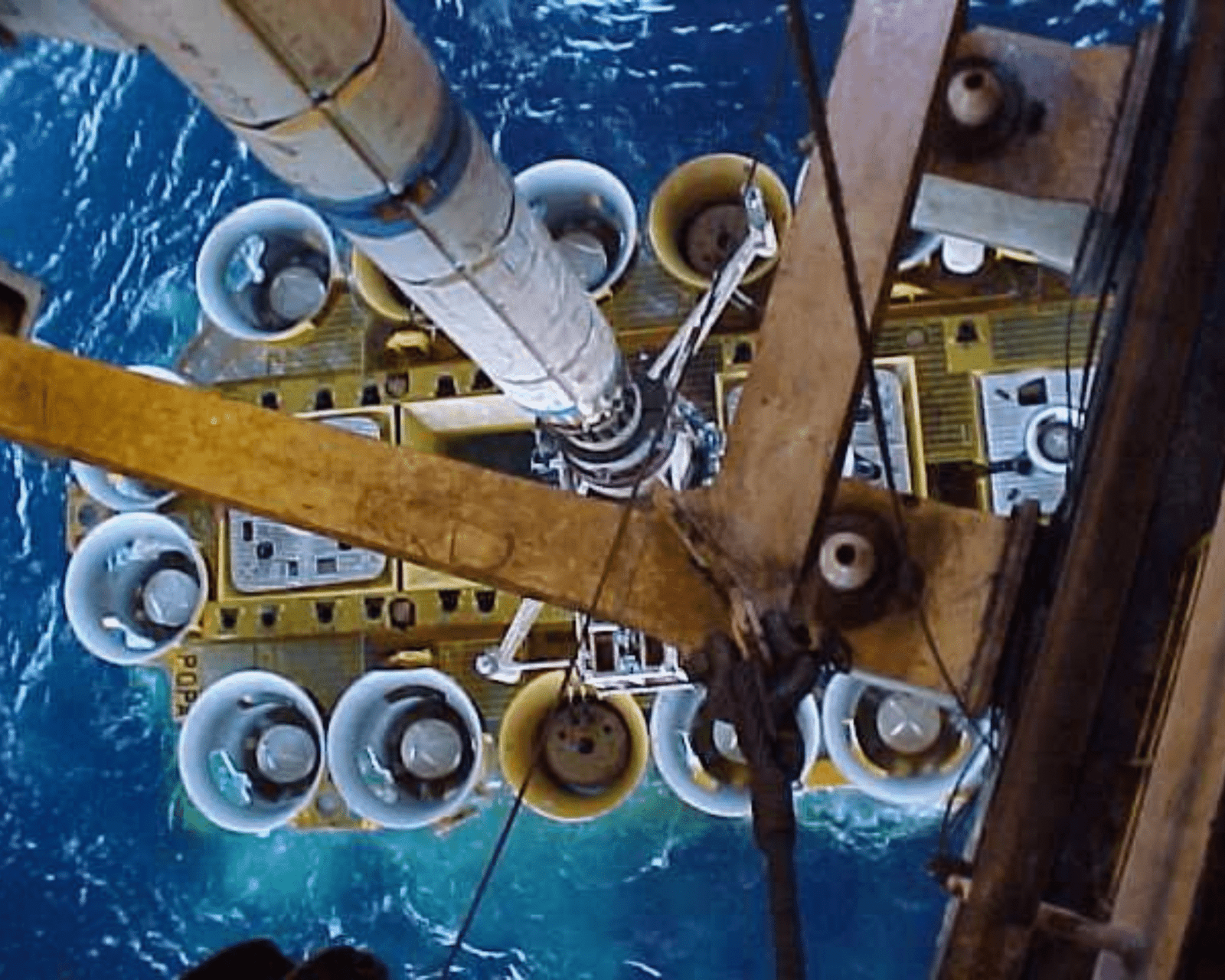

We design and upgrade equipment and systems to meet strict technical standards, extend lifecycle and cut operating costs. From surveys to full EPCC contracts, our engineering team turns complex challenges into robust, field-ready solutions.

- Upgrade equipment projects

- Technical surveys and assessments

- EPCC contracts (Engineering, Procurement, Construction and Commissioning)

- Management of Change (MOC)

Consulting

With decades of project experience, our consultants diagnose the real causes behind performance issues and build practical action plans. We help companies improve project execution, manufacturing processes and long-term reliability.

- Project management consulting

- Manufacturing and process improvement

Services – PSM (Preservation, Storage & Maintenance)

Maintenance is essential to ensure operational efficiency and the long-term sustainability of industrial activities. With growing pressure for environmental responsibility, preservation, storage and preventive maintenance play a key role in extending equipment lifecycle, reducing waste and cutting the carbon footprint of operations.

Preservation & Storage

Preserving equipment properly is critical to extend its useful life and avoid premature replacement. We design and implement storage and preservation routines that protect parts from humidity, extreme temperatures and dust, preventing corrosion and deterioration.

By refurbishing and reintegrating components into the operating cycle, we reduce the need for new materials and the emissions associated with manufacturing and transport.

- Proper storage: Equipment and spare parts should be stored in appropriate locations, protected from humidity, extreme temperatures and dust, which prevents corrosion and deterioration. This reduces the need for replacement parts and, consequently, the demand for materials that generate carbon

emissions during production.

- Lifecycle extension: By refurbishing equipment, worn components can be restored and reintegrated into the operating cycle, reducing the extraction of new materials and minimizing emissions (carbon footprint) associated with the

transportation and manufacture of new parts.

Preventive Maintenance

Our preventive maintenance programs focus on identifying potential failures before they become serious problems. In brownfield environments, this approach brings direct sustainability and performance benefits.

Well-maintained equipment runs more efficiently, consuming less fuel and electricity, and generating fewer greenhouse gas emissions. It also reduces unplanned downtime, avoiding costly emergency repairs and the extra CO₂ emissions linked to urgent logistics and replacements.

- Energy efficiency: Preventative maintenance improves equipment performance by ensuring that it operates efficiently and with reduced fuel and electricity consumption. Equipment in good condition tends to require less energy, which reduces greenhouse gas emissions associated with operation.

- Reduced downtime: Corrective maintenance, which is performed after equipment failure, requires more resources and produces higher carbon emissions due to the logistics of repair and possible replacements. Preventative maintenance reduces the chances of unplanned downtime and avoids extra CO2 emissions caused by unexpected failures.

Commissioning Services

From pre-commissioning to start-up, Cedro General Services supports clients in bringing critical equipment and systems into service safely and efficiently. Our multidisciplinary team prepares procedures, supervises installation and executes functional tests to verify that each component operates as designed and interfaces correctly with the rest of the system. This reduces start-up risks, minimizes rework and helps extend the life of your assets.

- Functional verification of equipment and systems

- Safe and efficient start-up of new installations

- Compliance with client specifications and international standards

Our partners:

Engineering

From the conceptual phase to repair and revision, our engineering team ensures that every project meets strict technical requirements and international standards. We combine proven experience with optimization practices focused on reducing carbon emissions and operating costs.

Our track record in complex projects allows us to deliver high-quality, reliable and cost-effective solutions, always aligned with real field conditions.

- Proposal and concept design

- 2D and 3D assembly drawings

- Detailed drawings and parametric analysis

- Upgrade projects for existing equipment

- Full EPCC (Engineering, Procurement, Construction and Commissioning)

- Management of Change (MOC) for brownfield projects

Industry Insight

Turning Losses into Performance

Corrosion and poor preservation practices cost industries over US$ 2.5 trillion every year in failures, downtime and premature replacement of equipment. In offshore and industrial environments, every unprotected valve, riser or subsea system accelerates this loss and increases HSE exposure.

Cedro designs preservation and maintenance programs that protect critical assets, extend lifecycle and directly support carbon footprint reduction by avoiding unnecessary repairs, rework and scrap.

ACTIVITY & SUSTAINABILITY

Global Services - Carbon Footprint reduction

Cedro General Services operates in several countries, supporting complex oil & gas projects while keeping a strong commitment to sustainability. Our team combines international experience with practices that reduce CO₂ emissions, proving it is possible to deliver high-performance engineering and protect the environment at the same time.

Global presence

We support clients in different countries, bringing proven solutions for brownfield projects, lifecycle extension and operational reliability wherever they are needed.

CO₂ reduction in practice

By extending equipment lifecycle, optimizing maintenance and storage and avoiding unnecessary replacements, we help operators do more with less carbon emissions.

Humans & environment aligned

Our approach connects safety, performance and environmental care: when assets are well preserved and processes are optimized, people, business and nature benefit together.